If you’ve never heard of LoRa, you’re not alone. Although it’s the hottest new communication technology on the market today, presenting a powerful alternative to old-timers like Bluetooth and Wi-Fi, it’s also relatively brand new.

Originally developed in 2012 and only just starting to make its way into mass market products, LoRa specializes in transmitting over long ranges (hence the name). In fact, LoRa devices can transmit over 10 miles with clear line-of-sight. This technology is also remarkable for its low-power consumption, energy efficiency, and low cost.

Most importantly for commercial kitchens and their food safety programs, LoRa also performs well in very difficult environments. Restaurants may not care about transmitting to a receiver located miles away, but they do need a device that can work from within a heavily insulated, stainless steel deep freezer.

In fact, many heavily insulated coolers are essentially Faraday cages that prevent electromagnetic signals from escaping; a LoRa-based wireless temperature sensor, however, can reliably transmit its signal even under these conditions. LoRa uses lower frequencies in the 868 and 915 MHz ranges, which are more successful at transmitting through heavy materials.

By contrast, although Bluetooth (which operates in the 2.4 GHz band) and Wi-Fi are the de facto standard for most wireless devices to communicate with other equipment or with the cloud, they can falter in these conditions. Indeed, before LoRa, remotely monitoring the temperature in a cold-holding unit often entailed making undesirable compromises, like drilling holes to run cable or setting up multiple antennas to extend the signal. Those efforts just add expense, labor, and potential points of failure – and could end up voiding equipment warranties.

LoRa requires none of that. It just works.

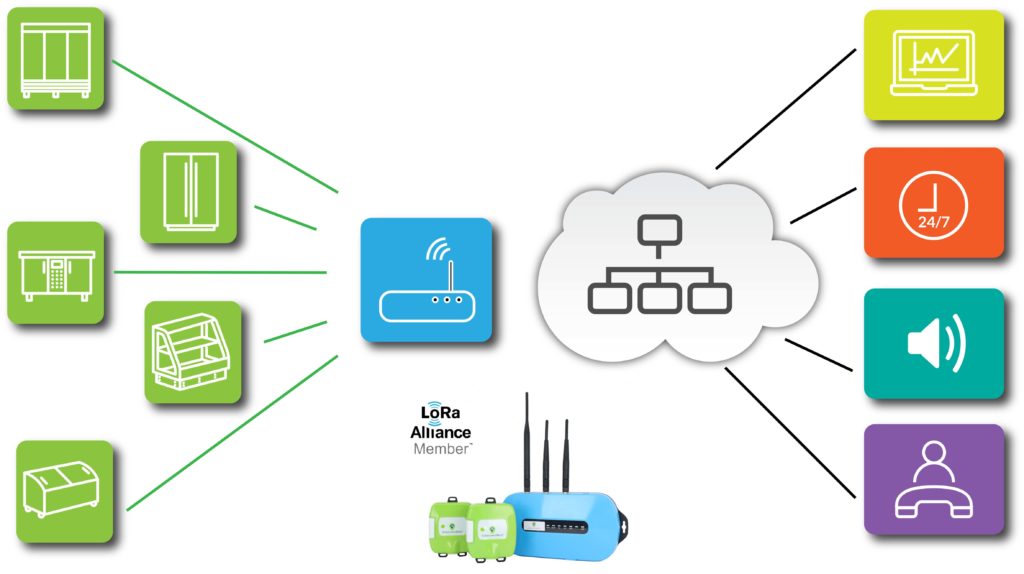

Digital, automated, and wireless food safety systems are proliferating in restaurant kitchens, thanks to their ability to provide better results, safer food, enhanced brand protection, and peace of mind that operations are shielded against food safety disasters. However, smart devices like temperature sensors cannot work if they cannot successfully and consistently communicate at all times.

The LoRa-enabled sensor “lives” fully in the environment it is monitoring, so no wiring, drilling, or extra equipment (like repeaters or external antennas) are required to get data from the device to the Cloud. LoRa sensors are also hardened against power grid issues; data can be stored on the device until power and/or internet connectivity is restored.

Altogether, LoRa presents exciting new opportunities for restaurants to get smart about their operations, implement more effective food safety systems, and drive greater efficiencies – without having to make the same kind of compromises Bluetooth and Wi-Fi can require.